Exploring the Revolution of Chiplet Technology

Introduction

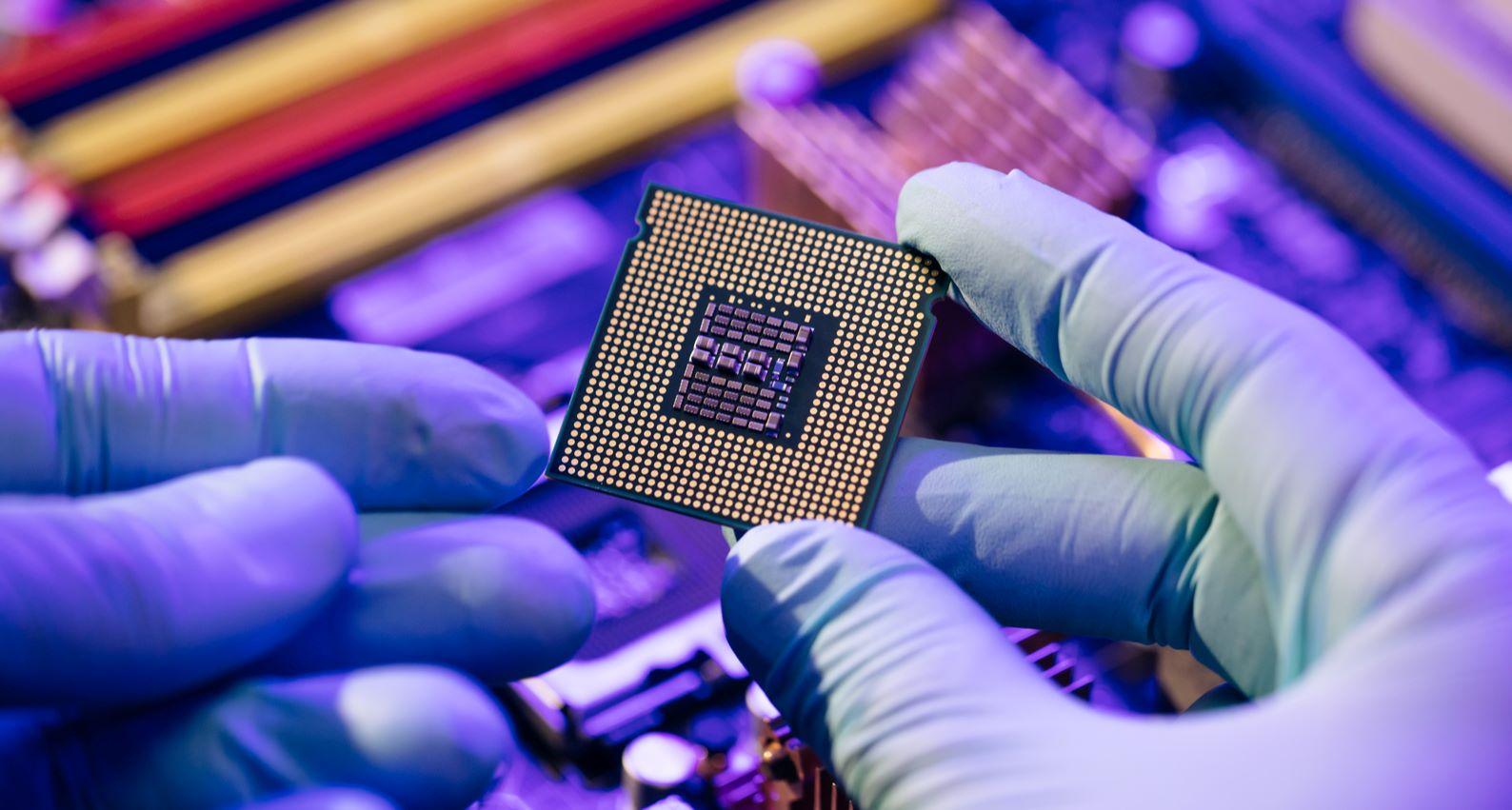

Chiplets represent a groundbreaking advancement in semiconductor design, offering a modular approach to building complex System-on-Chip (SoC) systems. Unlike traditional monolithic SoCs, chiplets are smaller, specialized chips that can be combined to create a comprehensive integrated circuit. This technology, still relatively new, holds immense promise and is currently under active development by various leading semiconductor companies.

Think of chiplets as the sophisticated equivalent of building blocks, akin to high-tech Legos. They allow for the decomposition of complex functions into smaller, highly specialized modules, each fulfilled by dedicated chiplets. By assembling these chiplets together, an integrated system encompassing data storage, signal processing, computing, and data flow management can be constructed.

In essence, a chiplet is a fundamental component within a packaging architecture, encompassing intellectual property (IP) subsystems, connected to other chiplets through package-level integration. Chiplet technology effectively integrates multiple electrical functions into a single package or system, revolutionizing chip design and system architecture.

Leveraging chiplet technology, engineers can design complex chips rapidly and cost-effectively by integrating various third-party IPs into a single chip or package. These third-party IPs can encompass I/O drivers, memory ICs, and processor cores, among others.

The origins of the chiplet concept can be traced back to DARPA’s CHIPS (Common Heterogeneous Integration and IP) project. Recognizing that advanced SoCs aren’t always suitable for small-scale applications, the CHIP plan sought to introduce a new paradigm for IP reuse, which ultimately led to the development of chiplets.

While conventional chipsets continue to dominate the realm of computer technology in most electronic devices today, it’s evident that this landscape is evolving. Many experts anticipate that specialized chiplets will become a commonplace feature in consumer devices as these advanced technologies unfold. Moreover, there are numerous reliable and cost-effective technologies available for designing chiplets.

Moore’s Law, originally proposed by Gordon Moore in 1965, predicted that the number of transistors on a microchip would double roughly every two years. This forecasted exponential increase in computing power and decrease in costs has been a driving force in the semiconductor industry. Chiplet technology can be viewed as a means to extend Moore’s Law and sustain the trend of enhancing performance while reducing costs.

One way in which chiplet technology contributes to extending Moore’s Law is by enabling the creation of more intricate and potent SoCs without the constraint of fitting all components onto a single monolithic chip. By breaking down a complex SoC into smaller, modular chiplets that interconnect seamlessly, it becomes feasible to continue scaling up the number of transistors and other essential components. This approach ensures that the semiconductor industry can keep pace with the performance improvements and cost reductions foreseen by Moore’s Law.

Today, the market for heterogeneous chiplet integration is experiencing rapid growth. Prominent microprocessors like AMD’s Epyc and Intel’s Lakefield are being manufactured in high volumes using chiplet designs and heterogeneous integration packaging technology. This underscores the increasing significance and potential of chiplet technology in shaping the future of semiconductor engineering.

A Brief History of Chiplet Technology

The concept of chiplets has been in existence for several decades, but it has garnered significant attention in recent years as an innovative approach to tackle the challenges associated with scaling down traditional monolithic Integrated Circuits (ICs). As Moore’s Law continues to drive the semiconductor industry forward, monolithic ICs have grown in size and complexity, resulting in higher production costs and increased manufacturing complexities. Chiplet-based design has emerged as a promising solution to these challenges, enabling companies to harness smaller, specialized chiplets that can be seamlessly combined to create complete systems.

Although the term “chiplet” is relatively new, having been coined only in the last five years, the concept has been brewing for some time. It was initially introduced by researchers and scientists at the University of Michigan, who embarked on a mission to enhance the design, efficiency, and functionality of computer chips. The name “chiplet” itself is a fusion of “chip” and “petite,” underscoring its small yet powerful nature. Chiplets have undergone rapid development over the past few years, leading many experts to anticipate their growing prominence as they potentially replace traditional chipsets in consumer devices, thanks to their enhanced capabilities.

In May 2007, DARPA (Defense Advanced Research Project Agency) initiated its COSMOS (compound semiconductor material on silicon) program, which marked the early foray into heterogeneous chiplets. DARPA’s CHIPS initiative, launched with the aim of creating modular computers using chiplets, addressed various integration standards, Intellectual Property (IP) blocks, and design tools in its pursuit of chiplet technology.

Advantages of Chiplets and Their Superiority

Chiplets present a multitude of significant advantages when compared to traditional monolithic processor designs. Their versatility, rapid customization, and ease of upgradeability contribute to reduced development timelines and cost efficiencies. One of the standout benefits is the enhancement of performance, achieved by employing specialized processing elements finely tuned for specific tasks. For instance, when demanding substantial processing power for AI applications, it’s conceivable to replace the conventional CPU with a chiplet meticulously engineered for AI-related tasks.

Beyond the performance boost, chiplets excel in shrinking processor size and power demands. By consolidating multiple functions into singular units, they eliminate the need for extensive wiring, cooling systems, and other components typically associated with conventional chips. This streamlines manufacturing processes, ultimately leading to reduced production costs and enabling compact device designs ideal for mobile applications like smartphones or AR/VR headsets.

The adaptability inherent in chiplet technology significantly benefits design and development endeavors. Due to their ease of customization and upgradability, chiplets empower manufacturers to swiftly respond to evolving market dynamics and emerging technological innovations. They simplify production by streamlining the steps required for designing and manufacturing customized System-on-Chip (SoC) solutions.

Moreover, chiplet technology holds the potential to enhance yield rates and cost-efficiency. This is achieved by enabling the use of smaller, specialized chiplets instead of a single, monolithic chip for specific tasks. Improved yield results from a streamlined manufacturing process, reducing the complexity and potential for defects, ultimately increasing the yield of functional chips. Additionally, the individual design and manufacturing of chiplets can be optimized, further enhancing overall yield.

Another cost-reduction avenue facilitated by chiplets is the ability for manufacturers to adopt a mix-and-match approach when creating SoCs. Instead of developing entirely new chips for each product, manufacturers can selectively combine existing chiplets to form the desired SoC, a process that is faster and more cost-effective. This approach proves particularly advantageous for companies requiring swift product launches and the agility to adapt SoCs rapidly in response to shifting market demands.

In summary, chiplets not only elevate performance but also drive efficiency gains in terms of size, power consumption, development timelines, manufacturing yield, and cost-effectiveness. Their versatile nature and adaptability make them a cornerstone of future semiconductor advancements.

Challenges in Chiplet Technology

Chiplet technology, while promising, is not without its share of challenges:

- Cost-Effective and Reliable Packaging: A primary challenge is ensuring the low cost and high reliability of chiplet-based packaging technology. Advanced packaging methods are crucial to the success of chiplet integration. This is exemplified by the strategic shift of leading semiconductor manufacturer TSMC towards investing in packaging technologies like InFo and CoWoS (Chip-on-Wafer-on-Substrate). Achieving cost efficiency without compromising reliability remains a top priority.

- Yield Management: Maintaining a high-quality product with an economical production rate is another critical challenge. While chiplets are known for their certification, yield management remains a concern. In a System-in-Package (SiP) configuration, the cost of the entire chiplet system can significantly escalate if issues are encountered with one of the chiplet silicon chips. Ensuring consistent yields across various chiplets is essential to control costs and enhance overall product reliability.

- Testing Coverage: The integration of multiple chiplets within a single package presents challenges in terms of testing coverage. Due to the limited number of pins available for each chiplet, some chiplets may become inaccessible for testing beyond their designated pins. This limitation can lead to difficulties in thoroughly testing and diagnosing potential issues within the chiplet system. Addressing this challenge is crucial for ensuring the robustness and quality of chiplet-based devices.

- Interconnect Complexity: Chiplet technology relies heavily on interconnectivity between chiplets to function cohesively. Managing the complexity of these interconnections, especially in high-performance systems, poses a significant challenge. Ensuring that data can be efficiently exchanged between chiplets while minimizing latency and power consumption requires innovative design and integration solutions.

- Standardization and Compatibility: Establishing industry-wide standards for chiplet technology is an ongoing challenge. Compatibility between chiplets from different manufacturers and ensuring seamless integration into diverse system architectures is vital. Achieving standardization can enhance the versatility and adoption of chiplet-based solutions across the semiconductor industry.

- Thermal Management: The compact nature of chiplet-based designs can lead to increased heat density. Efficient thermal management is essential to prevent overheating and maintain system reliability. Developing thermal solutions that effectively dissipate heat from densely packed chiplets is an ongoing challenge.

- Security and Trust: Ensuring the security and trustworthiness of chiplet-based systems is paramount. As chiplets may come from different sources, establishing mechanisms for secure communication and data protection within the chiplet ecosystem poses challenges. Preventing vulnerabilities and unauthorized access to sensitive data is an ongoing concern.

In summary, chiplet technology offers numerous advantages but is accompanied by several complex challenges related to packaging, yield management, testing, interconnectivity, standardization, thermal management, and security. Addressing these challenges is essential for realizing the full potential of chiplet-based systems in the semiconductor industry.

Distinguishing Chiplet from SoC Technology

Chiplet and System-on-Chip (SoC) are two distinct approaches in semiconductor design, each with its unique characteristics and advantages:

- Manufacturing Scale:

- SoC (System-on-Chip): In an SoC, all components and functionalities are integrated onto a single silicon die. This means that the entire system, including CPU, GPU, memory, I/O interfaces, and more, coexists on a monolithic chip.

- Chiplet: Chiplets, in contrast, are smaller-scale circuits manufactured separately from the main device. These chiplets are designed to perform specific functions or tasks and are interconnected using 3D stacking or advanced packaging technology. This modular approach allows for customization and scalability without affecting overall performance.

- Customization and Modularity:

- SoC: SoCs are typically less modular and customizable since all components are tightly integrated on a single chip. Customizing specific functions often requires redesigning the entire SoC.

- Chiplet: Chiplet designs are inherently modular and customizable. Each chiplet can be optimized individually, making it easier to tailor the device to specific requirements. For example, chiplets can be designed to be more power-efficient while maintaining performance levels. This flexibility is particularly advantageous for applications that do not demand high-performance circuitry.

- Manufacturability:

- SoC: SoCs, being a single integrated unit, may have a relatively straightforward manufacturing process.

- Chiplet: Chiplet manufacturing can be more complex due to the need to assemble and interconnect multiple chiplets. However, chiplet-based designs offer benefits in terms of yield optimization for each specific chiplet, potentially reducing manufacturing defects.

- Heterogeneous Chiplet Integration:

- Chip Split and Integration: In heterogeneous chiplet integration, the SoC logic is divided into multiple logics, which are then stacked together using methods like Chip on Wafer (CoW) or Wafer on Wafer (WoW) technology. This approach optimizes package area and electrical performance.

- Chip Partition and Integration: In this scheme, the SoC is partitioned into distinct functions, such as logic and I/Os, which are integrated using advanced packaging techniques. Logic and I/O chiplets are assembled on the same substrate within a single package.

- Advantages and Drawbacks:

- SoC: SoCs are well-suited for high-performance applications where integration is crucial. They simplify the design and manufacturing process but may lack the customization options offered by chiplets.

- Chiplet: Chiplets excel in scenarios where customization, modularity, and scalability are key. They can be more power-efficient and cost-effective for specific tasks. However, chiplet designs can introduce complexity in the manufacturing process and may face challenges related to interconnect reliability.

- Reliability Considerations:

- SoC: SoCs are less prone to reliability issues associated with interconnecting multiple modules, as all components are integrated on a single die.

- Chiplet: Chiplets, which rely on 3D stacking and advanced packaging for interconnection, may introduce reliability concerns, especially if one module fails, potentially impacting the entire device’s functionality.

In summary, the choice between Chiplet and SoC technology depends on the specific requirements of the application. Chiplets offer modularity, customization, and scalability, making them suitable for certain scenarios, while SoCs are preferred for high-performance, integrated applications. Both approaches have their advantages and challenges, and their selection should be based on the intended use case and design goals.

The Future of Chiplet Technology: Innovation and Transformation

The future of chiplet technology holds considerable promise, driven by ongoing technological advancements, market dynamics, and corporate strategies. While precise predictions are challenging, chiplet technology has the potential to bring about a transformative shift in the design and manufacturing of processors and electronic components.

One of the key transformative aspects of chiplet technology is its ability to introduce greater flexibility and efficiency into manufacturing processes. By enabling the mixing and matching of different chiplets to create customized products, chiplet technology can streamline production, reduce costs, and enhance resource utilization. This modularity also empowers companies to tailor their products with precision, selecting chiplets that align precisely with their performance and power requirements.

Moreover, chiplet technology paves the way for the development of highly specialized and customized electronic products. Companies can choose chiplets that best align with their unique needs, resulting in more efficient and targeted solutions. This potential for specialization is particularly relevant in an era where diverse and niche market demands are on the rise.

As technological innovation continues to propel the electronics industry forward, chiplet technology is expected to remain a focal point of development and innovation. Its ability to adapt to evolving market trends, optimize manufacturing processes, and cater to specific product requirements positions it as a significant driver of progress in the years ahead. While the exact path of chiplet technology’s evolution remains uncertain, its role as a catalyst for innovation within the electronics industry is likely to persist and flourish.

Summary

In essence, chiplet technology represents a revolutionary modular design approach. It involves the creation of small, self-contained units known as “chiplets,” each dedicated to a specific function. When these chiplets are combined, they give rise to larger and more complex systems tailored to unique requirements. Chiplet technology holds the promise of transforming the landscape of electronic component design and manufacturing by introducing greater efficiency, cost-effectiveness, and customization.

The advantages of chiplet technology are manifold. Firstly, it offers flexibility and scalability, enabling the assembly of components that precisely match performance and power needs. This translates into more streamlined and cost-efficient manufacturing processes, as products can be optimized for specific purposes.

Secondly, chiplet technology enhances device performance. By designing chiplets for specific tasks, it leads to quicker and more efficient operations. Moreover, it contributes to reduced power consumption through the efficient utilization of resources.

Ultimately, chiplet technology has the potential to catalyze innovation within the electronics industry. Through the creation of specialized and customized products, it opens doors to the development of novel technologies and solutions.

Reference :

Anysilicon [https://anysilicon.com/the-ultimate-guide-to-chiplets/]